Automotive

Arabian Automobiles Company expands presence at Dubai Industrial City with state-of-the-art distribution centre

Arabian Automobiles Company (AAC) has commenced the development of a parts distribution centre that will serve as a hub for industry innovation and excellence at Dubai Industrial City, the region’s leading manufacturing and logistics hub.

The project’s groundbreaking ceremony at Dubai Industrial City, part of TECOM Group PJSC, was attended by Saud Abu Alshawareb, Executive Vice President of Industrial at TECOM Group; Hussam Baghdad, Senior Director, Automotive at AW Rostamani; and Thierry Sabbagh, Divisional Vice President, President KSA, Middle East at Nissan and INFINITI.

Located on a land plot spanning more than 700,000 sq.ft., the logistics storage and distribution centre marks an expansion of AAC’s presence at Dubai Industrial City, where it already operates a central logistics centre, and reflects its commitment to providing enhanced customer services by strengthening its parts value chain for Nissan, INFINITI, Renault, and AWR Trading entities in the UAE.

The state-of-the-art centre will have a built-up area of more than 350,000 sq.ft. and upon completion in 2025, will house 150 employees to deliver enhanced safety, productivity, and commercial efficiencies in line with international operating standards.

“Prompt and seamless customer service will be the hallmark of excellence as global automotive demand continues to surge,” said Saud Abu Alshawareb, Executive Vice President of Industrial at TECOM Group, on behalf of Dubai Industrial City. “Carmakers around the world are pursuing operational efficiencies to enhance their competitiveness, and intelligent warehousing solutions have a crucial role to play in securing the automotive sector’s business continuity and future growth.

“AAC’s new advanced and automated facility in Dubai Industrial City’s automotive cluster will support the vision of Dubai Economic Agenda ‘D33’ to strengthen the value chains for domestic goods and services. Logistics facilities that leverage automation and advanced technologies will not only deliver improved efficiencies and capacity, but also contribute to the UAE’s trade activity, helping to reinforce its position as a global trading hub.”

Hussam Baghdad, Senior Director, Automotive at AW Rostamani, said: “Our investment in the new parts distribution centre marks a significant milestone in our journey towards automotive excellence – this state-of-the-art facility underscores our commitment to delivering unparalleled quality and service to our customers. By setting new benchmarks in logistics and distribution services, we’re enhancing operational efficiency and redefining the customer experience in the automotive industry, in line with the visionary leadership of the UAE that continues to nurture an environment conducive to innovation and progress.”

Thierry Sabbagh, Divisional Vice President, President Middle East, KSA, Nissan and INFINITI, said: “The ground-breaking of this cutting-edge facility underscores Nissan’s unwavering commitment to ensuring the availability of Nissan Genuine Parts in the region. The expansive facility and its substantial storage capacity not only strengthen Nissan’s business operations but, more importantly, benefits our customers. This strategic investment is a pivotal advancement in our partnership with Arabian Automobiles Company, and we look forward to continuing to drive our vision of innovation and excellence to significantly enhance customer satisfaction.”

UAE Headquartered, Group AMANA is the construction partner for this project. AMANA’s strategy for redesigning the pre-engineered steel building (PEB) structure involves implementing a modular methodology for assembly and erection, utilising off-site precast works for concrete elements, and integrating BIM for enhanced project coordination to enhance the project’s value by optimising efficiency and maintaining quality. AMANA’s proficiency in design and ability to oversee logistics and automation led to its selection as the project’s contractor, and with a commitment to delivering certainty, quality, and safety, AMANA aims to exceed expectations in every aspect of the project.

With the new facility, AAC joins an impressive roster of UAE-based business giants that are part of Dubai Industrial City, home to more than 1,000 local, regional, and international customers, in addition to over 300 operational factories.

The region’s leading manufacturing and logistics hub, Dubai Industrial City was launched in 2004 with an intelligent masterplan promoting cross-sector collaboration with dedicated zones for the base metals, machinery, minerals, F&B, transport, and chemical industries. Located close to Al Maktoum International Airport, Jebel Ali Port, an Etihad Rail freight terminal, and critical regional road networks, the ecosystem offers specialised infrastructure, including industrial land, storage, and logistics spaces that minimise waste and enable resource-efficiencies.

Dubai Industrial City is part of TECOM Group’s portfolio of business destinations that include Dubai Internet City, Dubai Media City, Dubai Studio City, Dubai Production City, Dubai Knowledge Park, Dubai International Academic City, Dubai Design District (d3), and Dubai Science Park.

Automotive

Arabian Automobiles Introduces Choice-Led Nissan Ramadan Offers Reflecting the Spirit of the Holy Month

Arabian Automobiles Company (AAC), the flagship automotive company of AW Rostamani Group and the exclusive dealer for Nissan in Dubai, Sharjah, and the Northern Emirates, has launched its Nissan Ramadan offers across selected models. Aligned with the spirit of generosity associated with the Holy Month, the campaign is structured around flexibility and choice.

Customers can select one of three ownership options based on their priorities, whether that is added reassurance through complimentary insurance and service, greater ease in monthly planning with 0% interest rate over three to five years, or a savings option across selected models. Businesses, fleet owners and logistics operators can also benefit from these Ramadan offers, with value-led advantages such as 5-year warranty, 5-year service, and 5-year roadside assistance extending the same spirit of flexibility to commercial needs.

This approach reflects AAC’s considered interpretation of value, recognising that customer needs and circumstances differ, and that choice plays a central role in how value is defined during Ramadan.

The offers span a broad lineup, including Altima, Kicks, Magnite, Pathfinder, Patrol, X-TERRA, and X-TRAIL, with savings ranging from AED 6,000 up to AED 25,000. For those seeking a more performance-led experience, the Nissan Z is also included, also with savings of up to AED 50,000.

That same spirit of care continues beyond the showroom, with seasonal after-sales advantages. Customers coming in for an interval service or a free inspection will be eligible for a one-year, 24/7 roadside assistance membership covering Dubai, Sharjah, and the Northern Emirates.

Keeping convenience in mind, Arabian Automobiles is offering a buy-four-get-one promotion on maintenance contracts to make long-term upkeep more manageable, alongside up to 65% off parts for additional repairs. Flexible payment options are available through Tabby and selected credit card plans, and a gift is included with any Nissan accessory purchase. Customers are invited to explore the Ramadan campaign at their nearest Nissan of Arabian Automobiles showroom.

Automotive

UDRIVE PARTNERS WITH AGMC TO INTRODUCE MINI VEHICLES TO ITS CAR-SHARING FLEET IN THE UAE

Udrive, the UAE’s leading car-sharing platform, has signed a strategic partnership with AGMC, the official importer of MINI in Dubai, Sharjah and the Northern Emirates, to introduce MINI vehicles to Udrive’s shared mobility fleet in the UAE. The collaboration was formalised through a Memorandum of Understanding (MoU) between Udrive and AGMC and brings the MINI brand — the iconic British-heritage premium automotive brand within the BMW Group, renowned for its distinctive design and engaging driving experience — into the car-sharing space, supporting a shared ambition to expand access to premium urban mobility solutions across the country.

The partnership will see a total of 100 MINI vehicles progressively introduced to the Udrive platform, with an initial fleet already available to customers across the UAE. The lineup will include MINI Convertibles, bringing the experience of open-top driving into the car-sharing space, alongside other MINI models well-suited to urban mobility and everyday city use. Through the Udrive platform, customers benefit from an all-inclusive car-sharing experience, with fuel and parking covered as part of the service.

By expanding flexible access to premium mobility, the partnership supports the UAE’s broader ambitions for smarter, more connected cities, in line with the vision outlined in the Dubai Master Urban Plan 2040. The collaboration reflects a growing shift toward agile, shared and experience-led mobility solutions, complementing evolving urban lifestyles and mobility needs.

Hasib Khan, Founder and CEO of Udrive, said: “At Udrive, innovation is about giving customers real choice and flexibility. Our platform is designed to adapt to how people live, whether that means enjoying a convertible over the weekend or choosing a practical vehicle during the week. Partnering with AGMC MINI allows us to bring distinctive premium vehicles to more customers and support the UAE’s vision for flexible and efficient urban mobility.”

Ziad Boghdady, Head of AGMC MINI, said: “Our collaboration with Udrive introduces a new way for customers to experience the MINI brand. Integrating MINI models into a car-sharing platform reflects changing preferences in the UAE, where access and flexibility are increasingly valued alongside design and performance, complementing MINI’s distinctive design and engaging driving experience. The partnership demonstrates AGMC MINI’s commitment to supporting modern mobility solutions that fit the needs of today’s urban lifestyles.”

Through the MoU, users will gain access to a range of MINI models via the Udrive platform, including Cooper S and John Cooper Works variants, as well as MINI Convertibles. Introducing convertibles into the car-sharing space expands the scope of shared mobility experiences, offering customers the opportunity to enjoy open-top driving on a flexible, on-demand basis.

Udrive enables customers to locate, book, and unlock vehicles through its mobile app, with flexible by-the-minute or by-the-day rentals. The service includes free fuel, free parking, and no deposit, removing common barriers associated with traditional car rentals. Udrive now operates a fleet of 2,000+ cars and has completed over three million rentals to date. In 2025 alone, the platform recorded over 554,000 trips and more than 45 million kilometres driven, reflecting growing demand for flexible mobility across the UAE.

Udrive continues to differentiate itself through exclusive partnerships, first-to-market initiatives, and value-led offerings that expand customer choice. Promoting car sharing as an alternative to private car ownership helps optimise vehicle usage, reduce congestion, and lower the overall environmental footprint by encouraging shared access over individual ownership.

Automotive

BALANCING TRADITION AND TECHNOLOGY: THE NEXT GENERATION TRANSFORMING AUTOMOTIVE WORKSHOPS

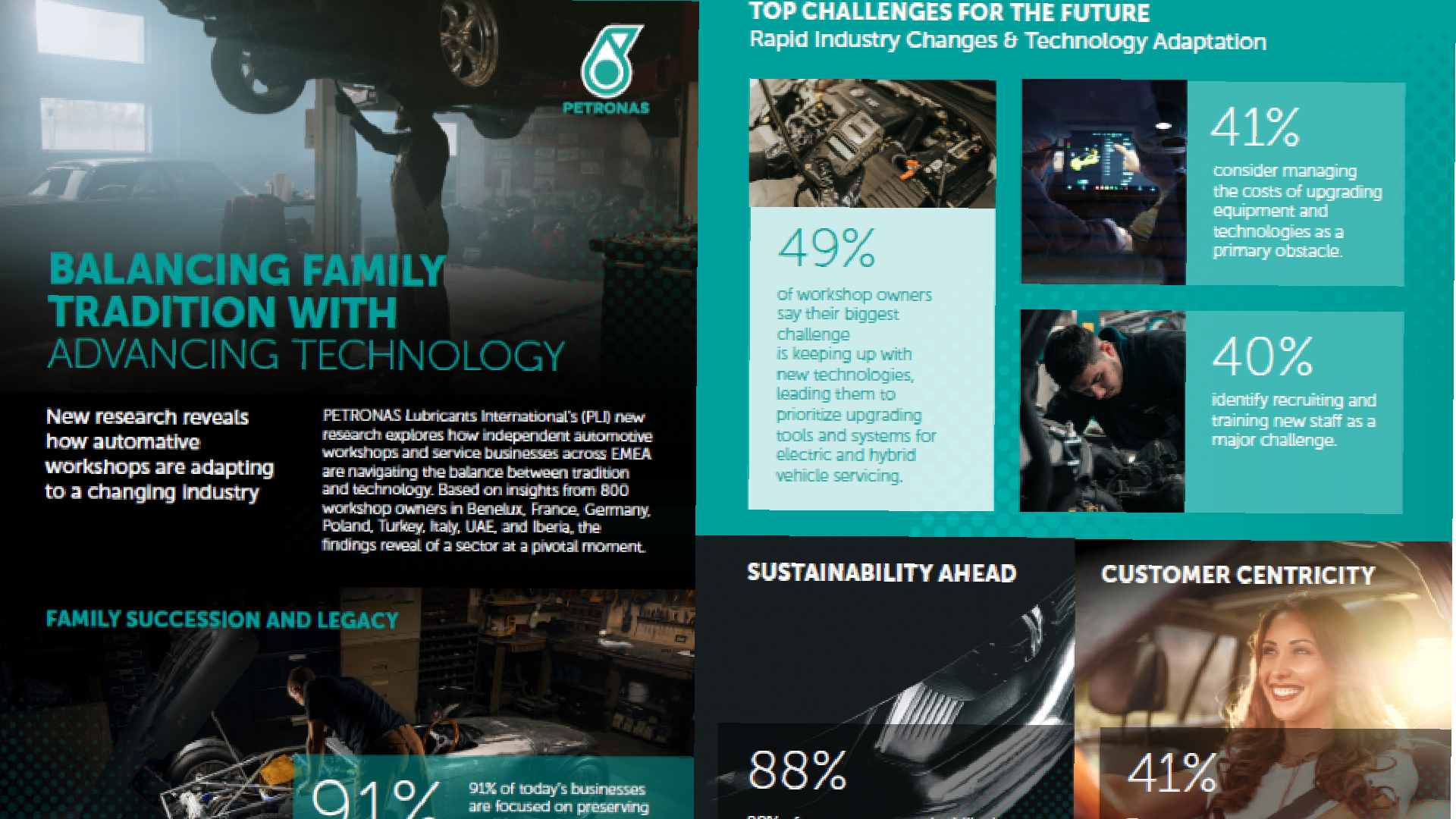

PETRONAS Lubricants International (PLI) today unveils new research exploring how independent automotive workshops and service businesses across EMEA are navigating the balance between tradition and technology. Based on insights from 800 workshop owners in Benelux, France, Germany, Poland, Turkey, Italy, the UAE, and Iberia, the findings reveal the sector is at a pivotal moment.

Nearly all workshop owners believe that protecting their reputation and values, as part of a family or community tradition, is paramount. This sense of legacy is particularly strong in Turkey (96%), the UAE (96%), and Iberia (95%.) The findings reveal a deep emotional connection among the next generation and new mechanics entering the industry, who are committed to preserving the skills and standards of their predecessors. Whilst at the same time, demonstrating the powerful blend of tradition and innovation which drives the sector.

The research, commissioned by PLI, reveals that owners are also acutely aware of the need to stay up to date with today’s technological advancements. This is where the energy and talent of younger generations become truly invaluable. Their passion for innovation and natural fluency with digital tools can transform what might seem like a challenge into an exciting new chapter for the industry. By actively investing in young talent and embracing their fresh perspectives, workshops can become vibrant hubs of progress, bridging digital and technological gaps, and leading the way in both the digital and green transitions shaping the automotive sector.

Nearly three in five (59%) owners report their workshop is seen as a trusted service provider locally but tradition alone isn’t enough to secure the future. With the industry changing fast, almost half (49%) of workshop owners say their biggest challenge is keeping up with new technologies. From electric and hybrid vehicles to digital systems and advanced diagnostics, the pressure to modernize is real. It’s also compounded by the struggle to find and train skilled staff, an issue flagged by nearly half of respondents (40%). For younger professionals entering the industry, this gap represents an opportunity to carve out a future in a sector hungry for fresh talent and innovation. Embracing the tech savviness and adaptability of younger workshop owners not only bridges existing gaps but also opens doors for further training and job opportunities, empowering workshops to evolve, driving a better future for all.

Despite the challenges of staffing, there’s a strong sense of optimism in the sector. Owners are determined to blend the best of the past with the demands of the future. More than a third (35%) say that putting the customer first remains their top priority, even as they navigate new territory. They’re finding ways to balance tradition with innovation, ensuring their workshops stay relevant and resilient.

“Independent workshops are the backbone of the automotive industry, and their ability to evolve by bringing in younger generations is inspiring. The research that PLI has commissioned shows that while heritage and trust remain at the heart of these businesses, owners are embracing innovation, from electric vehicles to digital tools and sustainable practices. At PLI, we’re committed to supporting this transformation by providing solutions that help workshops stay competitive, relevant, and true to their values.” said Giuseppe Pedretti, Regional Managing Director EMEA, PETRONAS Lubricants International

Sustainability is a defining theme for the sector, with nearly nine in ten (88%) workshop owners considering it essential in daily operations and customer communications. As consumers become more environmentally conscious, integrating sustainable practices is crucial for long-term growth, reputation, and alignment with global goals. Accelerating this transition requires investing in younger workshop owners, who bring fresh perspectives, digital expertise, and enthusiasm for innovation, supported by targeted training.

Empowering the next generation goes beyond adapting to change; it ignites a shared passion for the future and ensures workshops remain central to a dynamic, evolving industry. As the automotive landscape transforms, PLI stands as a trusted partner, offering solutions that reflect the values and ambitions of both established owners and emerging talent, driving real-world success.

-

Tech News2 years ago

Tech News2 years agoDenodo Bolsters Executive Team by Hiring Christophe Culine as its Chief Revenue Officer

-

News10 years ago

SENDQUICK (TALARIAX) INTRODUCES SQOOPE – THE BREAKTHROUGH IN MOBILE MESSAGING

-

VAR11 months ago

VAR11 months agoMicrosoft Launches New Surface Copilot+ PCs for Business

-

Tech Interviews2 years ago

Tech Interviews2 years agoNavigating the Cybersecurity Landscape in Hybrid Work Environments

-

Tech News8 months ago

Tech News8 months agoNothing Launches flagship Nothing Phone (3) and Headphone (1) in theme with the Iconic Museum of the Future in Dubai

-

Automotive1 year ago

Automotive1 year agoAGMC Launches the RIDDARA RD6 High Performance Fully Electric 4×4 Pickup

-

VAR2 years ago

VAR2 years agoSamsung Galaxy Z Fold6 vs Google Pixel 9 Pro Fold: Clash Of The Folding Phenoms

-

Tech News2 years ago

Tech News2 years agoBrighton College Abu Dhabi and Brighton College Al Ain Donate 954 IT Devices in Support of ‘Donate Your Own Device’ Campaign