Automotive

World’s Oldest Bentley T-Series Returns Home

The world’s oldest Bentley T-Series, a standard saloon in Shell Grey, has returned to Crewe after 59 years. Sensitively recommissioned and retaining much of its original componentry and running gear, it takes its place in the Bentley Heritage Collection of road- and race-cars that together describe all 105 years of Bentley’s history.

T-Series chassis number SBH1001 was used as a company trials car and featured in the original press coverage following the model launch at the 1965 Paris Salon de l’Auto. When found under a cover in storage, the car had not run for decades and was missing several key areas – including its entire interior. The car’s significance as the first T-Series – or equivalent Rolls Royce Silver Shadow – off the production line prompted the decision to recommission it, preserving as much of the original car as possible.

Mike Sayer, Head of the Bentley Heritage Collection, explains: “The T-Series is one of the final two pieces of the puzzle to complete our rejuvenated Heritage Collection. Our Chief Communications Officer, Wayne Bruce and I quite literally found it under a tarpaulin in the back of a warehouse, and given it was the first-of-line chassis we knew we had to save it. Together with our T-Series Mulliner Coupe, this revitalised sedan completes the Bentley heritage story of the 1960s and 1970s, and is now an outstanding example of the model, which was the first Bentley to use a unitary monocoque construction.”

After a group of Bentley apprentices started the process of dismantling and assessing the car, the recommissioning of the T-Series was entrusted to the expert team at P&A Wood, specialists in the preservation and restoration of classic Bentleys and the company’s partner for Heritage Collection projects. Louise Wood, daughter of co-founder Andrew Wood, led the project, supported by Coachwork manager Dave Lowe – a P&A Wood veteran of 23 years.

Restored to Prime Condition

Taking stock of the T-Series Bentley, key elements of the drivetrain proved to be in surprisingly good condition. The engine burst into life after a 15-year silence, needing only a thorough service, and the gearbox simply required minor adjustment. The rear axle too was in a good state and only needed new seals.

Major challenges for the team included a missing dashboard, no interior trim, a wiring loom in pieces without a detailed diagram, corrosion around the rear subframe and previous poor-quality crash repairs. With few replacement parts available off-the shelf, the team sourced a donor vehicle that was at the end of its life. As the specification of the T-Series evolved over the years, it was important that the donor should also be an early model. Every detail was discussed and pored over, right down to the correct (Rolls-Royce) logo on the seat belt buckles and the lack of wing mirrors.

The T Series featured innovative vibration-deadening Vibrashock mounts and a two-circuit hydro-pneumatic ride height control, all of which were thoroughly overhauled. All hydraulic hoses were replaced, and unique components like the brake distribution valves were restored to full working condition. Rewiring and fitting the dashboard proved a major undertaking, requiring huge amounts of time and perseverance.

Meanwhile the paintwork was stripped, revealing poorly executed accident repair work and inconsistent panel gaps. One rear wing was corroded and had to be replaced, after which the entire vehicle was given multiple coats of 2k high build primer, each coat being carefully sanded down once dry. ‘We spent a lot of time softening the panel edges, so they don’t look carved out of filler,’ Dave Lowe explains. ‘And though we’re using modern two-pack finishes, we tried to do everything in the old Crewe way.’ That included a final sand down with 8000 grit abrasive followed by machine polishing. Brightwork and bumpers were cleaned and polished, but not re-chromed – preserving the original patina.

That story now begins a new chapter, as the T-Series is reunited with its former press office registration number of 1900 TU as the latest addition to the Heritage Collection. Along with the 45 other cars in the Collection, the T-Series will live on Bentley’s campus in Crewe, England, on permanent display and kept in running, road legal condition to enable driving when needed.

The Bentley T-Series

In 1958, work began on designing the first monocoque Bentley and Rolls-Royce, destined to replace coachbuilt bodies underpinned by a separate chassis. The result was the car sold by Bentley as the T-Series and by Rolls-Royce as the Silver Shadow. By 1962, John Blatchley – famous for styling the R-Type Continental – had completed a new exterior design for a steel and aluminium monocoque body. The design improved on the passenger space of the preceding S3, but with the overall car now seven inches shorter, five inches lower and three and a half inches narrower.

Using the freshly developed 225 bhp, 6.23-litre V8 engine, seven prototypes undertook significant testing including endurance runs of over 100,000 miles. At the time the engine achieved the highest specific output by weight of any production car in the world of 2.7 lb/hp (1.2 kg/hp). Design innovations included separate sub frames to carry the engine and transmission, suspension, steering and rear axle assemblies, with ‘Vibrashock’ rubber sub frame mounts developed to isolate road noise and vibration.

The Bentley T-Series was hailed as a clear example of revolutionary engineering given it was the first Bentley to move away from a separate chassis build, and its relatively lightweight construction gave impressive performance for a four-sedan in 1965, with a maximum speed of 115 mph and 0-62 mph achieved in 10.9 seconds. 1,868 examples of the first-generation T-Series were produced, with a pre-tax list price of £5,425 and the majority being standard four-door saloons.

Automotive

UDRIVE PARTNERS WITH AGMC TO INTRODUCE MINI VEHICLES TO ITS CAR-SHARING FLEET IN THE UAE

Udrive, the UAE’s leading car-sharing platform, has signed a strategic partnership with AGMC, the official importer of MINI in Dubai, Sharjah and the Northern Emirates, to introduce MINI vehicles to Udrive’s shared mobility fleet in the UAE. The collaboration was formalised through a Memorandum of Understanding (MoU) between Udrive and AGMC and brings the MINI brand — the iconic British-heritage premium automotive brand within the BMW Group, renowned for its distinctive design and engaging driving experience — into the car-sharing space, supporting a shared ambition to expand access to premium urban mobility solutions across the country.

The partnership will see a total of 100 MINI vehicles progressively introduced to the Udrive platform, with an initial fleet already available to customers across the UAE. The lineup will include MINI Convertibles, bringing the experience of open-top driving into the car-sharing space, alongside other MINI models well-suited to urban mobility and everyday city use. Through the Udrive platform, customers benefit from an all-inclusive car-sharing experience, with fuel and parking covered as part of the service.

By expanding flexible access to premium mobility, the partnership supports the UAE’s broader ambitions for smarter, more connected cities, in line with the vision outlined in the Dubai Master Urban Plan 2040. The collaboration reflects a growing shift toward agile, shared and experience-led mobility solutions, complementing evolving urban lifestyles and mobility needs.

Hasib Khan, Founder and CEO of Udrive, said: “At Udrive, innovation is about giving customers real choice and flexibility. Our platform is designed to adapt to how people live, whether that means enjoying a convertible over the weekend or choosing a practical vehicle during the week. Partnering with AGMC MINI allows us to bring distinctive premium vehicles to more customers and support the UAE’s vision for flexible and efficient urban mobility.”

Ziad Boghdady, Head of AGMC MINI, said: “Our collaboration with Udrive introduces a new way for customers to experience the MINI brand. Integrating MINI models into a car-sharing platform reflects changing preferences in the UAE, where access and flexibility are increasingly valued alongside design and performance, complementing MINI’s distinctive design and engaging driving experience. The partnership demonstrates AGMC MINI’s commitment to supporting modern mobility solutions that fit the needs of today’s urban lifestyles.”

Through the MoU, users will gain access to a range of MINI models via the Udrive platform, including Cooper S and John Cooper Works variants, as well as MINI Convertibles. Introducing convertibles into the car-sharing space expands the scope of shared mobility experiences, offering customers the opportunity to enjoy open-top driving on a flexible, on-demand basis.

Udrive enables customers to locate, book, and unlock vehicles through its mobile app, with flexible by-the-minute or by-the-day rentals. The service includes free fuel, free parking, and no deposit, removing common barriers associated with traditional car rentals. Udrive now operates a fleet of 2,000+ cars and has completed over three million rentals to date. In 2025 alone, the platform recorded over 554,000 trips and more than 45 million kilometres driven, reflecting growing demand for flexible mobility across the UAE.

Udrive continues to differentiate itself through exclusive partnerships, first-to-market initiatives, and value-led offerings that expand customer choice. Promoting car sharing as an alternative to private car ownership helps optimise vehicle usage, reduce congestion, and lower the overall environmental footprint by encouraging shared access over individual ownership.

Automotive

BALANCING TRADITION AND TECHNOLOGY: THE NEXT GENERATION TRANSFORMING AUTOMOTIVE WORKSHOPS

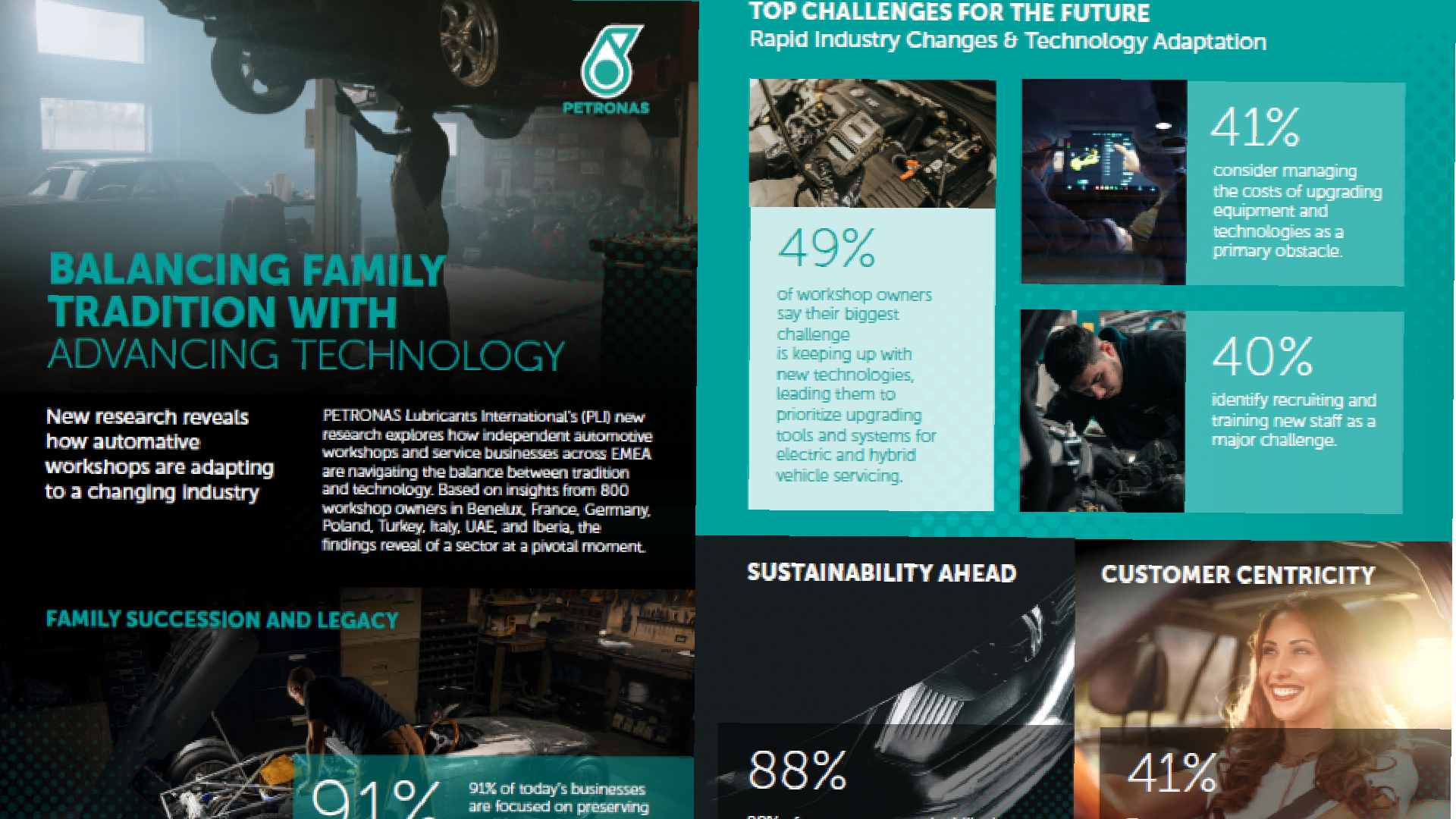

PETRONAS Lubricants International (PLI) today unveils new research exploring how independent automotive workshops and service businesses across EMEA are navigating the balance between tradition and technology. Based on insights from 800 workshop owners in Benelux, France, Germany, Poland, Turkey, Italy, the UAE, and Iberia, the findings reveal the sector is at a pivotal moment.

Nearly all workshop owners believe that protecting their reputation and values, as part of a family or community tradition, is paramount. This sense of legacy is particularly strong in Turkey (96%), the UAE (96%), and Iberia (95%.) The findings reveal a deep emotional connection among the next generation and new mechanics entering the industry, who are committed to preserving the skills and standards of their predecessors. Whilst at the same time, demonstrating the powerful blend of tradition and innovation which drives the sector.

The research, commissioned by PLI, reveals that owners are also acutely aware of the need to stay up to date with today’s technological advancements. This is where the energy and talent of younger generations become truly invaluable. Their passion for innovation and natural fluency with digital tools can transform what might seem like a challenge into an exciting new chapter for the industry. By actively investing in young talent and embracing their fresh perspectives, workshops can become vibrant hubs of progress, bridging digital and technological gaps, and leading the way in both the digital and green transitions shaping the automotive sector.

Nearly three in five (59%) owners report their workshop is seen as a trusted service provider locally but tradition alone isn’t enough to secure the future. With the industry changing fast, almost half (49%) of workshop owners say their biggest challenge is keeping up with new technologies. From electric and hybrid vehicles to digital systems and advanced diagnostics, the pressure to modernize is real. It’s also compounded by the struggle to find and train skilled staff, an issue flagged by nearly half of respondents (40%). For younger professionals entering the industry, this gap represents an opportunity to carve out a future in a sector hungry for fresh talent and innovation. Embracing the tech savviness and adaptability of younger workshop owners not only bridges existing gaps but also opens doors for further training and job opportunities, empowering workshops to evolve, driving a better future for all.

Despite the challenges of staffing, there’s a strong sense of optimism in the sector. Owners are determined to blend the best of the past with the demands of the future. More than a third (35%) say that putting the customer first remains their top priority, even as they navigate new territory. They’re finding ways to balance tradition with innovation, ensuring their workshops stay relevant and resilient.

“Independent workshops are the backbone of the automotive industry, and their ability to evolve by bringing in younger generations is inspiring. The research that PLI has commissioned shows that while heritage and trust remain at the heart of these businesses, owners are embracing innovation, from electric vehicles to digital tools and sustainable practices. At PLI, we’re committed to supporting this transformation by providing solutions that help workshops stay competitive, relevant, and true to their values.” said Giuseppe Pedretti, Regional Managing Director EMEA, PETRONAS Lubricants International

Sustainability is a defining theme for the sector, with nearly nine in ten (88%) workshop owners considering it essential in daily operations and customer communications. As consumers become more environmentally conscious, integrating sustainable practices is crucial for long-term growth, reputation, and alignment with global goals. Accelerating this transition requires investing in younger workshop owners, who bring fresh perspectives, digital expertise, and enthusiasm for innovation, supported by targeted training.

Empowering the next generation goes beyond adapting to change; it ignites a shared passion for the future and ensures workshops remain central to a dynamic, evolving industry. As the automotive landscape transforms, PLI stands as a trusted partner, offering solutions that reflect the values and ambitions of both established owners and emerging talent, driving real-world success.

Automotive

HOW FAR CAN AI DRIVE THE AUTOMOTIVE SECTOR?

Co-authored by: Giuseppe Pedretti (Regional Managing Director EMEA, PLI) & Ravi Tallamraju (Chief Technology Officer, PLI)

The conversations around AI in the automotive industry are often associated with self-driving cars. Yet, it’s the behind-the-scenes applications of AI, from design and diagnostics to driver experience and operational strategy, that are proving to be far more transformative.

Predictive maintenance has emerged as one of AI’s most powerful contributions to the sector. By continuously analysing telematic and operational data, AI enables early detection of mechanical stressors and anticipates component failures before they escalate. This foresight empowers fleet managers and workshops to schedule interventions with precision, minimising service interruptions, extending vehicle longevity, and curbing unnecessary expenditure.

AI-driven maintenance strategies are reshaping operational resilience, providing benefits such as real-time issues diagnosis, automated service reminders, and refined route efficiency, In fact, over half of fleet managers cite predictive analytics as a key lever for reducing overheads and enhancing performance, with nearly a third identifying AI and machine learning as the most influential technologies in fleet management over the next five years. From voice-enabled assistants that coach drivers to connected cameras that detect fatigue, the scope of predictive tools is expanding and ushering in a new era of intelligent, preventative care across the mobility landscape.

These innovations are especially critical for a sector that has faced considerable turbulence. In 2024, the automotive industry grappled with factory closures, supply chain fragmentation, and declining production across Europe and the West. Consumer demand softened under affordability pressures, while rising component costs and inflation compressed margins across the value chain, from workshops to fleet operators. Meanwhile, intensifying competition from Chinese manufacturers continues to push Western businesses to innovate and streamline.

Some argue AI has contributed to these pressures, but is also key to overcoming them. Its ability to convert data into strategic insights and automate complex workflows is helping businesses regain competitiveness, uncover new revenue streams, and reimagine their operating models.

Shifting Gears with AI

By 2032, the global automotive AI market is projected to reach $405 billion, with roughly 75% of automotive enterprises experimenting with at least one GenAI application. While major players are deploying AI across product design, supply chain optimisation, and customer engagement, fast accelerating smaller businesses stand to gain the most.

For these companies, the focus is on enhancing practical tools that drive measurable efficiency. Vehicle telematics, for example, enables workshops to diagnose issues in real time, store service histories, and anticipate future maintenance needs. This reduces reactive repairs and improves outcomes for customers and stakeholders alike.

Another area gaining traction is inventory intelligence. AI-powered forecasting tools analyse historical and repair data to predict parts demand with increasing accuracy. This not only prevents overstocking but ensures critical components are available when needed.

Fleet managers are equally enthusiastic as AI helps maintain uptime, optimise routes, and improve safety. Generative AI is powering in-vehicle voice assistants that guide drivers, flag risky behaviour, and even offer coaching. Connected cameras now detect signs of fatigue or distraction, reducing risk exposure and potential legal liabilities.

In-car connected services are also surging, with adoption expected to grow from 60% in 2024 to over 90% of new vehicles featuring voice assistants by 2028.

Why AI Belongs in Automotive Operations

The numbers speak volumes: the global market for automotive AI is forecasted to grow from $44 billion in 2025 to $74.5 billion by 2030. But beyond the figures, the rationale is clear.

Efficiency is a key driver of change. AI automates routine diagnostics, speeds up service checks, and simplifies documentation – allowing skilled personnel to focus on higher-value tasks. At the same time, these intelligent systems continue to learn and improve over time.

Safety is equally critical. Traditionally, the industry has taken a reactive approach, fixing problems only after they occur. AI transforms this model by enabling proactive vehicle management by detecting potential risks early, preventing failures, and ensuring compliance with increasingly strict safety regulations.

Cost control remains a key priority. In a margin-sensitive industry, even minor delays or downtime can erode profitability. AI helps minimise idle time, identify inefficient driving behaviours, and deliver more precise diagnostics. With fuel costs accounting for up to 40% of fleet expenses, AI plays a crucial role in pinpointing and eliminating waste, leading to more reliable operations and healthier bottom lines.

Still, adoption isn’t universal. Complex tools, fragmented data, and constrained budgets pose real challenges, especially for smaller players who rely more on experience than analytics. That’s precisely where AI excels: transforming existing knowledge into actionable intelligence.

How PETRONAS Lubricants International Uses AI

As a lubricant specialist, PETRONAS Lubricants International (PLI) leverages AI to accelerate R&D. Our models simulate lubricant performance under varied operating conditions, trained on extensive datasets of compositions. This allows us to predict outcomes before physical testing, sometimes revealing unexpected applications beyond automotive.

Smart tech and IoT devices also enable us to forecast lubricant degradation and advise customers on optimal service timing. Our Oil Condition Monitoring (OCM) system analyses samples for contaminants and wear metals, identifying potential issues before they become costly failures. Expert technicians deliver tailored reports that guide oil drain intervals and ensure consistent performance across fleets and machinery. This proactive approach enhances efficiency and extends equipment lifespan through intelligent, data-backed insights.

Internally, AI supports our production health: minimising waste, optimising throughput, and helping us meet sustainability goals by avoiding unnecessary downtime.

What More Can AI Do?

The potential of AI in automotive services is just beginning to unfold. The innovations we have achieved in lubricants alone demonstrate what is possible. As data becomes more accessible and algorithms more refined, even small operations will compete on insight, not just infrastructure. And as those innovations ripple across the sector, the competitive landscape will shift. That shift is coming. Best to be ready and in a position to lead.

-

Tech News2 years ago

Tech News2 years agoDenodo Bolsters Executive Team by Hiring Christophe Culine as its Chief Revenue Officer

-

VAR10 months ago

VAR10 months agoMicrosoft Launches New Surface Copilot+ PCs for Business

-

News10 years ago

SENDQUICK (TALARIAX) INTRODUCES SQOOPE – THE BREAKTHROUGH IN MOBILE MESSAGING

-

Tech Interviews2 years ago

Tech Interviews2 years agoNavigating the Cybersecurity Landscape in Hybrid Work Environments

-

Tech News7 months ago

Tech News7 months agoNothing Launches flagship Nothing Phone (3) and Headphone (1) in theme with the Iconic Museum of the Future in Dubai

-

VAR1 year ago

VAR1 year agoSamsung Galaxy Z Fold6 vs Google Pixel 9 Pro Fold: Clash Of The Folding Phenoms

-

Tech News2 years ago

Tech News2 years agoBrighton College Abu Dhabi and Brighton College Al Ain Donate 954 IT Devices in Support of ‘Donate Your Own Device’ Campaign

-

Automotive1 year ago

Automotive1 year agoAGMC Launches the RIDDARA RD6 High Performance Fully Electric 4×4 Pickup