Automotive

Maximum transparency: Mercedes-Benz is the world’s first car manufacturer to X-ray a crash test.

The technical sensation begins with a very loud bang. At 60 km/h, a device with a crash barrier rams into the orange C-Class saloon and hits it full on the side. Crash tests are always something special – even for the experts. But the spectacular part of this side impact test is located in a frame on the hall ceiling above the vehicle: A linear accelerator serves as an X-ray camera. Together with the Fraunhofer-Institute for High-Speed Dynamics, the EMI (Ernst Mach Institute) in Freiburg, Mercedes-Benz has now carried out the world’s first X-ray crash with a real car. On board was one SID II dummy on the left-hand side facing the impact. This is a test specimen with a female anatomy, specially designed for side impact tests.

This technology demonstration (proof of concept) at the EMI research crash facility in Freiburg has shown that high-speed X-ray technology can be used to visualise highly dynamic internal deformation processes. Previously invisible deformations and their exact processes thus become transparent. The numerous, high-resolution images allow precise analysis.

“The Mercedes-Benz X-ray crash sets a milestone in the development tools of the future. With a direct view into the hidden interior, it can help to draw important conclusions for the further improvement of vehicle safety. Mercedes-Benz thus confirms its role as a safety pioneer in automotive engineering.”Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer

“The successful X-ray crash provides us with valuable insights to further optimize our technology for capturing previously inaccessible information. Fraunhofer EMI is thus consistently pursuing its strategy of using high-speed X-ray imaging to make dynamic processes visible.” Dr. Malte Kurfiß, Head of Crash Test Centre, Fraunhofer EMI

“The world’s first X-ray crash shows that X-ray technology can provide revealing new insights. We learn what happens inside a vehicle and to the dummies during an accident. The X-ray images also offer the opportunity to further improve the model quality of the digital prototypes.” Prof. Dr Paul Dick, Director of Vehicle Safety, Mercedes-Benz AG

Ultrashort X-ray technology: up to 1,000 images per second

For several years, the Mercedes-Benz vehicle safety division has been researching the use of X-ray technology in crash tests together with colleagues from EMI. The decisive factor for the breakthrough was the use of a linear accelerator with 1 kHz technology as the radiation source. The device is far more powerful than the X-ray flashes previously used in trials: The photon energy of the linear accelerator is up to nine megaelectron volts. This allows all materials commonly used in vehicle construction to be screened. The duration of the X-ray pulse is only a few microseconds. This makes it possible to record deformation processes in the crash test without motion blur. The linear accelerator also generates a continuous stream of these X-ray pulses. This means that up to 1,000 images per second are possible. That is about 1,000 times as many as with conventional X-ray procedures.

During the crash test, the beams shine through the bodywork and any dummies from above. A flat detector is located under the test vehicle. It serves as a digital image receiver in the X-ray system: When the radiation hits the detector, an electrical signal is generated. The intensity of this depends on how strongly the radiation was previously absorbed by the vehicle and dummy structure. This influences the grey value that is later visible – similar to the X-ray inspection of luggage at the airport or images of this kind taken by a doctor.

In the milliseconds of the actual impact time, the X-ray system shoots around 100 still images. Combined into a video, they provide highly exciting insights into what happens inside safety-relevant components and in the dummy’s body during a crash. In this way, it is possible to observe in detail how the thorax of the dummy is pressed in or how a component is deformed. The important part on the way from research to industrial application is the fact that the X-ray crash does not affect any other analysis tools. Even the interior cameras in the crash test vehicle record without any disturbance.

The EMI experts drew up a comprehensive radiation protection concept for the X-ray crash. Dosimeters are used as monitors to ensure that employees are not exposed to radiation. The government authority has approved the operation of the plant in accordance with legal requirements. The elaborate physical protection measures include an additional 40-centimetre-thick concrete wall around the building and a protection door weighing around 45 tonnes.

Crash tests: Part of Mercedes-Benz’s “Real Life Safety” philosophy

On 10 September 1959, the first crash test in the history of Mercedes-Benz took place – on open ground close to the plant in Sindelfingen. A test car was driven head-on into a solid obstacle. This opened a new chapter in safety research at Mercedes-Benz, as it made it possible to study the crash behaviour of both vehicles and occupants under realistic conditions using test cars and dummies. Together with the analyses of the Group’s own accident research, crash tests form the basis for the “Real Life Safety” philosophy.

Mercedes-Benz currently carries out up to 900 crash tests per year and around 1,700 “sled tests” at the Vehicle Safety Technology Centre in Sindelfingen. In this crash simulation, a test sled is accelerated and braked. A test object (vehicle body shell or assembly) is mounted on the sled and subjected to the forces arising during a real vehicle crash. These sled tests allow non-destructive testing of individual components, especially restraint systems such as seat belts.

And the world’s first public crash test on two fully electric vehicles in autumn 2023 shows that safety at Mercedes-Benz is not a question of the drive system. EQA and EQS SUV models crash into each other in a real accident scenario at a speed of 56 km/h and an overlap of 50 per cent. The test confirms the high level of occupant protection: The passenger cell and high-voltage battery of both vehicles remain intact as intended, the doors can be opened, and the high-voltage systems switch off automatically.

About the Fraunhofer-Institute for High-Speed Dynamics, the Ernst Mach Institute (EMI)

The Fraunhofer EMI specialises in the physics, engineering and computer science of fast processes in experiments and simulations. The aim is to develop solutions for industrial applications with a focus on reliability, safety, resilience, efficiency and sustainability.

The Fraunhofer EMI deals with crash, impact and shock wave phenomena across all materials. Adopting a comprehensive approach, the institute analyses and optimises the entire range of materials and microstructures through to complex structures. Applications range from materials to components, cars, aeroplanes, satellites, buildings, urban systems and infrastructure networks.

The Fraunhofer Society is the leading organisation for applied research in Europe. Under its umbrella, 76 institutes and research facilities work at locations throughout Germany. More than 30,000 employees generate an annual research volume of more than 2.9 billion euros.

Automotive

Arabian Automobiles Introduces Choice-Led Nissan Ramadan Offers Reflecting the Spirit of the Holy Month

Arabian Automobiles Company (AAC), the flagship automotive company of AW Rostamani Group and the exclusive dealer for Nissan in Dubai, Sharjah, and the Northern Emirates, has launched its Nissan Ramadan offers across selected models. Aligned with the spirit of generosity associated with the Holy Month, the campaign is structured around flexibility and choice.

Customers can select one of three ownership options based on their priorities, whether that is added reassurance through complimentary insurance and service, greater ease in monthly planning with 0% interest rate over three to five years, or a savings option across selected models. Businesses, fleet owners and logistics operators can also benefit from these Ramadan offers, with value-led advantages such as 5-year warranty, 5-year service, and 5-year roadside assistance extending the same spirit of flexibility to commercial needs.

This approach reflects AAC’s considered interpretation of value, recognising that customer needs and circumstances differ, and that choice plays a central role in how value is defined during Ramadan.

The offers span a broad lineup, including Altima, Kicks, Magnite, Pathfinder, Patrol, X-TERRA, and X-TRAIL, with savings ranging from AED 6,000 up to AED 25,000. For those seeking a more performance-led experience, the Nissan Z is also included, also with savings of up to AED 50,000.

That same spirit of care continues beyond the showroom, with seasonal after-sales advantages. Customers coming in for an interval service or a free inspection will be eligible for a one-year, 24/7 roadside assistance membership covering Dubai, Sharjah, and the Northern Emirates.

Keeping convenience in mind, Arabian Automobiles is offering a buy-four-get-one promotion on maintenance contracts to make long-term upkeep more manageable, alongside up to 65% off parts for additional repairs. Flexible payment options are available through Tabby and selected credit card plans, and a gift is included with any Nissan accessory purchase. Customers are invited to explore the Ramadan campaign at their nearest Nissan of Arabian Automobiles showroom.

Automotive

UDRIVE PARTNERS WITH AGMC TO INTRODUCE MINI VEHICLES TO ITS CAR-SHARING FLEET IN THE UAE

Udrive, the UAE’s leading car-sharing platform, has signed a strategic partnership with AGMC, the official importer of MINI in Dubai, Sharjah and the Northern Emirates, to introduce MINI vehicles to Udrive’s shared mobility fleet in the UAE. The collaboration was formalised through a Memorandum of Understanding (MoU) between Udrive and AGMC and brings the MINI brand — the iconic British-heritage premium automotive brand within the BMW Group, renowned for its distinctive design and engaging driving experience — into the car-sharing space, supporting a shared ambition to expand access to premium urban mobility solutions across the country.

The partnership will see a total of 100 MINI vehicles progressively introduced to the Udrive platform, with an initial fleet already available to customers across the UAE. The lineup will include MINI Convertibles, bringing the experience of open-top driving into the car-sharing space, alongside other MINI models well-suited to urban mobility and everyday city use. Through the Udrive platform, customers benefit from an all-inclusive car-sharing experience, with fuel and parking covered as part of the service.

By expanding flexible access to premium mobility, the partnership supports the UAE’s broader ambitions for smarter, more connected cities, in line with the vision outlined in the Dubai Master Urban Plan 2040. The collaboration reflects a growing shift toward agile, shared and experience-led mobility solutions, complementing evolving urban lifestyles and mobility needs.

Hasib Khan, Founder and CEO of Udrive, said: “At Udrive, innovation is about giving customers real choice and flexibility. Our platform is designed to adapt to how people live, whether that means enjoying a convertible over the weekend or choosing a practical vehicle during the week. Partnering with AGMC MINI allows us to bring distinctive premium vehicles to more customers and support the UAE’s vision for flexible and efficient urban mobility.”

Ziad Boghdady, Head of AGMC MINI, said: “Our collaboration with Udrive introduces a new way for customers to experience the MINI brand. Integrating MINI models into a car-sharing platform reflects changing preferences in the UAE, where access and flexibility are increasingly valued alongside design and performance, complementing MINI’s distinctive design and engaging driving experience. The partnership demonstrates AGMC MINI’s commitment to supporting modern mobility solutions that fit the needs of today’s urban lifestyles.”

Through the MoU, users will gain access to a range of MINI models via the Udrive platform, including Cooper S and John Cooper Works variants, as well as MINI Convertibles. Introducing convertibles into the car-sharing space expands the scope of shared mobility experiences, offering customers the opportunity to enjoy open-top driving on a flexible, on-demand basis.

Udrive enables customers to locate, book, and unlock vehicles through its mobile app, with flexible by-the-minute or by-the-day rentals. The service includes free fuel, free parking, and no deposit, removing common barriers associated with traditional car rentals. Udrive now operates a fleet of 2,000+ cars and has completed over three million rentals to date. In 2025 alone, the platform recorded over 554,000 trips and more than 45 million kilometres driven, reflecting growing demand for flexible mobility across the UAE.

Udrive continues to differentiate itself through exclusive partnerships, first-to-market initiatives, and value-led offerings that expand customer choice. Promoting car sharing as an alternative to private car ownership helps optimise vehicle usage, reduce congestion, and lower the overall environmental footprint by encouraging shared access over individual ownership.

Automotive

BALANCING TRADITION AND TECHNOLOGY: THE NEXT GENERATION TRANSFORMING AUTOMOTIVE WORKSHOPS

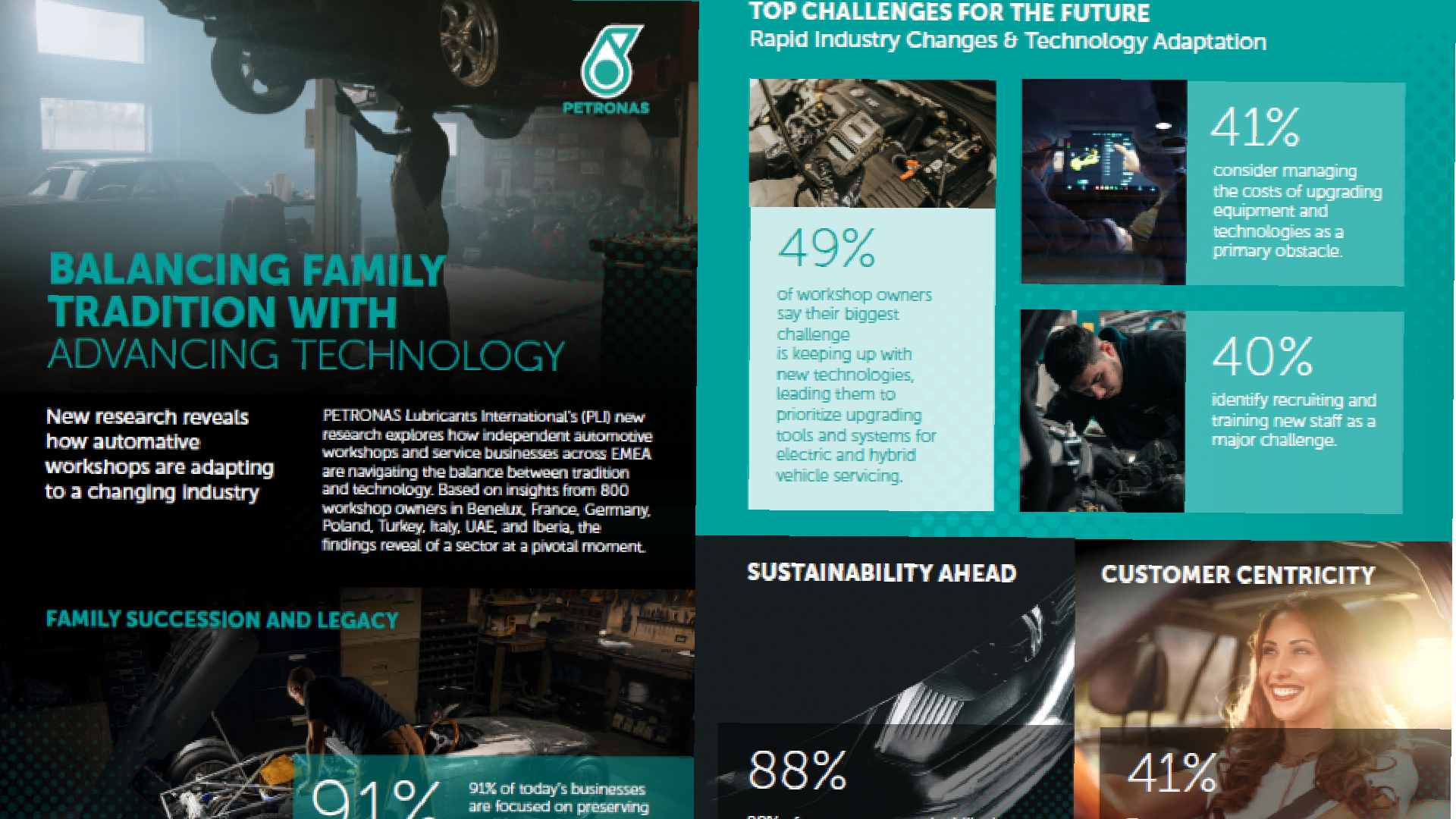

PETRONAS Lubricants International (PLI) today unveils new research exploring how independent automotive workshops and service businesses across EMEA are navigating the balance between tradition and technology. Based on insights from 800 workshop owners in Benelux, France, Germany, Poland, Turkey, Italy, the UAE, and Iberia, the findings reveal the sector is at a pivotal moment.

Nearly all workshop owners believe that protecting their reputation and values, as part of a family or community tradition, is paramount. This sense of legacy is particularly strong in Turkey (96%), the UAE (96%), and Iberia (95%.) The findings reveal a deep emotional connection among the next generation and new mechanics entering the industry, who are committed to preserving the skills and standards of their predecessors. Whilst at the same time, demonstrating the powerful blend of tradition and innovation which drives the sector.

The research, commissioned by PLI, reveals that owners are also acutely aware of the need to stay up to date with today’s technological advancements. This is where the energy and talent of younger generations become truly invaluable. Their passion for innovation and natural fluency with digital tools can transform what might seem like a challenge into an exciting new chapter for the industry. By actively investing in young talent and embracing their fresh perspectives, workshops can become vibrant hubs of progress, bridging digital and technological gaps, and leading the way in both the digital and green transitions shaping the automotive sector.

Nearly three in five (59%) owners report their workshop is seen as a trusted service provider locally but tradition alone isn’t enough to secure the future. With the industry changing fast, almost half (49%) of workshop owners say their biggest challenge is keeping up with new technologies. From electric and hybrid vehicles to digital systems and advanced diagnostics, the pressure to modernize is real. It’s also compounded by the struggle to find and train skilled staff, an issue flagged by nearly half of respondents (40%). For younger professionals entering the industry, this gap represents an opportunity to carve out a future in a sector hungry for fresh talent and innovation. Embracing the tech savviness and adaptability of younger workshop owners not only bridges existing gaps but also opens doors for further training and job opportunities, empowering workshops to evolve, driving a better future for all.

Despite the challenges of staffing, there’s a strong sense of optimism in the sector. Owners are determined to blend the best of the past with the demands of the future. More than a third (35%) say that putting the customer first remains their top priority, even as they navigate new territory. They’re finding ways to balance tradition with innovation, ensuring their workshops stay relevant and resilient.

“Independent workshops are the backbone of the automotive industry, and their ability to evolve by bringing in younger generations is inspiring. The research that PLI has commissioned shows that while heritage and trust remain at the heart of these businesses, owners are embracing innovation, from electric vehicles to digital tools and sustainable practices. At PLI, we’re committed to supporting this transformation by providing solutions that help workshops stay competitive, relevant, and true to their values.” said Giuseppe Pedretti, Regional Managing Director EMEA, PETRONAS Lubricants International

Sustainability is a defining theme for the sector, with nearly nine in ten (88%) workshop owners considering it essential in daily operations and customer communications. As consumers become more environmentally conscious, integrating sustainable practices is crucial for long-term growth, reputation, and alignment with global goals. Accelerating this transition requires investing in younger workshop owners, who bring fresh perspectives, digital expertise, and enthusiasm for innovation, supported by targeted training.

Empowering the next generation goes beyond adapting to change; it ignites a shared passion for the future and ensures workshops remain central to a dynamic, evolving industry. As the automotive landscape transforms, PLI stands as a trusted partner, offering solutions that reflect the values and ambitions of both established owners and emerging talent, driving real-world success.

-

Tech News2 years ago

Tech News2 years agoDenodo Bolsters Executive Team by Hiring Christophe Culine as its Chief Revenue Officer

-

News10 years ago

SENDQUICK (TALARIAX) INTRODUCES SQOOPE – THE BREAKTHROUGH IN MOBILE MESSAGING

-

VAR11 months ago

VAR11 months agoMicrosoft Launches New Surface Copilot+ PCs for Business

-

Tech Interviews2 years ago

Tech Interviews2 years agoNavigating the Cybersecurity Landscape in Hybrid Work Environments

-

Tech News8 months ago

Tech News8 months agoNothing Launches flagship Nothing Phone (3) and Headphone (1) in theme with the Iconic Museum of the Future in Dubai

-

Automotive1 year ago

Automotive1 year agoAGMC Launches the RIDDARA RD6 High Performance Fully Electric 4×4 Pickup

-

VAR2 years ago

VAR2 years agoSamsung Galaxy Z Fold6 vs Google Pixel 9 Pro Fold: Clash Of The Folding Phenoms

-

Tech News2 years ago

Tech News2 years agoBrighton College Abu Dhabi and Brighton College Al Ain Donate 954 IT Devices in Support of ‘Donate Your Own Device’ Campaign